Fruit of the Loom Sustainable

|

We believe a more sustainable fruity future is here for everyone. Being ethical and environmentally friendly has been The Fruit Way for a long time, so we are excited to be sharing a new campaign with you that highlights the positive action we have taken in recent years, plus our commitment to ambitious new sustainability goals for 2025 and 2030. |

|

|||||

|

|

As of 2018, our annual target has been to divert at least 95% of our waste from dumpsites - for all our facilities, from manufacturing to distribution and offices. To measure our company-wide commitment in terms of waste disposal, we use the criteria set out in the Zero Waste International Alliance business recognition programme, which requires 90% or more of all discarded resources to be diverted from landfill. We are pleased to report that we managed to exceed the Zero Waste target for the fourth consecutive year and, better still, also exceeded our own higher target of 95%. One of the ways we have been able to achieve this is by reducing waste in our manufacturing processes. We use technology that allows us to cut patterns more efficiently, resulting in less waste, and we work with 3D modelling software, reducing the need for product samples. The textile waste we create is sent to be recycled into new yarn fibres or reused, for example to make padding for car seats or mattresses. We have also fundamentally redesigned our packaging, eliminating polybags and cardboard liners. Where we absolutely cannot do without packaging, we have worked on more sustainable and recycled materials. We know that developing ways to further eliminate waste has a positive impact on our commitment to sustainability, and we continue to invest in initiatives and technology to help us minimise waste products as part of our global efforts to ensure a more fruitful future for all. |

|||||

|

Diversity and inclusion makes us stronger As an international employer, Fruit of the Loom promotes a dynamic, culturally rich and diverse working environment. With employees from 16 countries, inclusion, diversity and equality are of paramount importance to us - with opportunities for all, regardless of gender, age or ethnicity. Based on a company-wide culture of togetherness and teamwork, Fruit of the Loom also attaches great importance to nurturing a friendly relaxed working atmosphere. In the garment industry, women make up the majority of the workforce, so it is important to us that this is reflected in our senior roles. At Fruit of the Loom, we nurture both our male and female colleagues through ongoing training, such as our Fruit of the Loom University programme. We are also committed to creating a workplace where everyone is treated with respect and empowered to contribute equally, open to all.

As a global company, we strongly believe that our differences make us stronger, and we promote diversity and inclusion practices in our organisation. We promote a culture of connectedness for all employees, regardless of background, and we focus on attracting, retaining and developing diverse talent. |

|

|||||

|

More than ever, people are wondering where their clothes come from, how they are made and who makes them. The good news is that we at Fruit of the Loom have been making our own garments The Fruit Way for years. Following our long tradition of manufacturing, we moved to our own large-scale, purpose-built European production facility in Morocco in 2008. Here, vertically integrated full control over production means we can ethically control the quality, colour and consistency of the Ts, Sweats and Polos our customers rely on. But, more importantly, it means we can make our collections fairly and with respect for the people we work with, along with a dedicated focus on sustainability and eco-friendly production. |

|||||

|

Today, we employ more than 4,000 people in Morocco, all of whom receive fair wages, excellent and safe working conditions, training, fair working hours and additional benefits, including healthcare and free transport. Together, the team produces millions of garments every week; and we are proud to say that just over 90% of our garments are made entirely by us. All this means you can choose the high-quality Fruit of the Loom clothes you trust, with complete confidence and reassurance that they are made the right way - The Fruit Way. |

|

|||||

|

Ethical production Ethical production has always been important to us. Like our outstanding iconic T-shirts and inexpensive T's to our premium polos and classic sweats, most of our garments are made entirely by us in our purpose-built factory in Morocco, where we operate to the highest ethical and environmental standards. For other garments from around the world, we work with many other suppliers from around the world. But it is vital to us that these are all independently verified according to our strict code of ethics. We only work with companies that meet our high sustainability and environmental standards, and those that are committed to worker safety and fair pay - without child or forced labour. This is all supported by our certifications with credible independent rating organisations such as WRAP and OEKO-TEX®. We are also members of both Amfori and Better Cotton, which gives extra confidence when working with Fruit of the Loom. |

|||||

|

Since 2012, we have published 100% of the suppliers we work with so that all our customers can order from us with confidence. We are still one of only a third of clothing companies worldwide to do this - and by 2025 we have the ambitious goal of reducing all our global suppliers to raw materials. Full transparency is just one of the ways we are working to make a real difference to the garment industry to create a more fruitful future for all. |

|

|||||

|

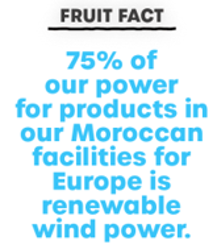

Another part of The Fruit Way to a more sustainable future is about using renewable energy wherever possible. Therefore, we are pleased to report that 75% of our current energy used to produce products for Europe, in our Moroccan facilities, is renewable - this means using the natural power of the wind!

|

|||||

|

In Morocco, at our purpose-built garment factory, our state-of-the-art wastewater treatment plant enables us to reuse up to 60% of wastewater. Using technology designed for our needs, the wastewater recovery process uses activated sludge as pretreatment, plus sand filtration, ultrafiltration and reverse osmosis. This process is generally used in seawater and surface water desalination. We are one of the few companies in the world using such a process to recycle brackish paint water to reduce consumption and help conserve natural resources. |

|

|||||

Fruit of the Loom Certificates:

|

|

|

|

||||||

Fruit of the Loom Certificates (PDF downloads):

|

|

|

|||||||

Fruit of the Loom reports & statements (PDF downloads):

| FotL Sustainability Report 2021 |

FotL Code Of Conduct Statement |

FotL Human Trafficking & Modern Disclosure Statement |

||||||

0

0